The short of this is I am looking for a cheaper option for an AC box seeing as that I have 2 defenders now that need AC.

Condenser, drier, compressor, trinary switches lines, etc, are all available as a generic item for the DIYer. But a complete HVAC box is defender specific item, I've been looking at options in aftermarket like vintage air, but I cannot figure something that I think I can shoehorn inside a Puma dash, or can be easily adapted to mount in the engine bay on the bulkhead.

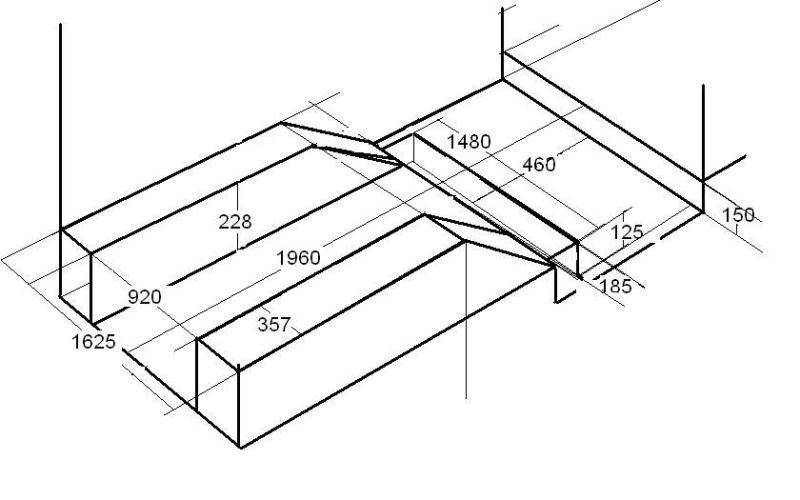

To that end I am considering fabricating a replacement hvac box. I'm not looking to manufacture these for sale, I'm hoping to come up with an open source design that other DIY fabricators could build.

The box design can be cut from sheetmetal with a few bends on a brake. Anyone who can get metal cut from a DXF ought to be able to get the sheet metal cut in a flat pattern. Bending into the correct shape could be done with a proper CNC press brake, manual brake, or by hand.

So the 3 off the shelf elements I am trying to source to make this happen are:

Centrifugal fan

Heater Core.

Ac Evaporator.

I've been looking at options from common vehicles that could be adapted to fit in a defender sized hvac box. This GM unit with expansion valve from a picture seems like it would work, but the dimensions are unknown, and the expansion block valve doesnt have standard #6, #8 type threaded fittings, so finding a mating fitting to makeup a hose might be an issue.

![Image]()

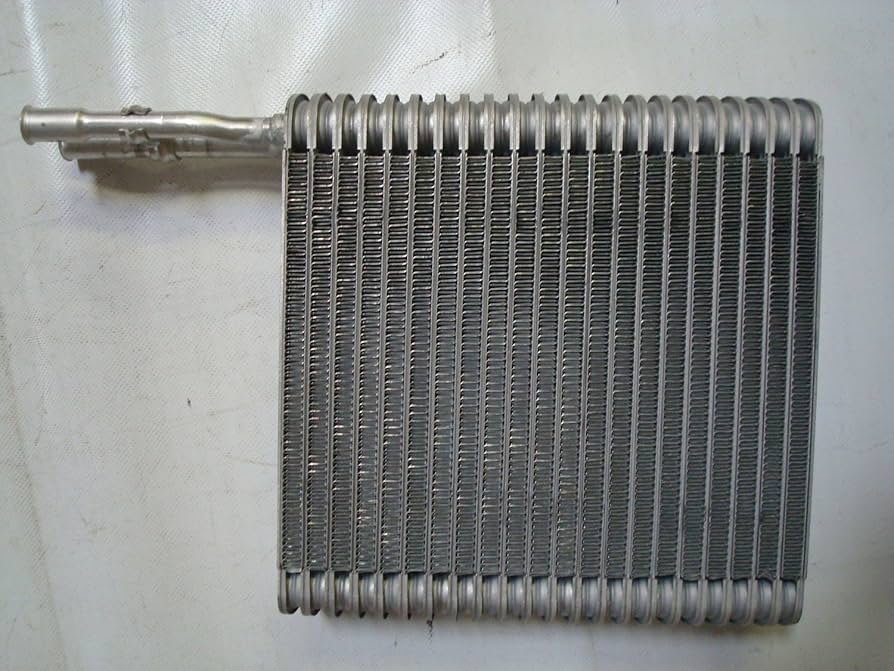

I know from experence that the 1996- Jeep XJ has an evaporator that connects directly to a TXV with more standard threaded fittings:

![Image]()

And the 1997+ XJ changed fittings and uses an orifice tube instead:

![Image]()

So there is a plethora of off the shelf options, but hard to find information on dimensions online, and many newer vehicles use push lock and other less standard fittings that are a little more trouble for us in the aftermarket world. I'm also not keen on trying to do an orifice tube in an aftermarket application, my gut says sticking with TXV will work better than trying to size an orifice.

Condenser, drier, compressor, trinary switches lines, etc, are all available as a generic item for the DIYer. But a complete HVAC box is defender specific item, I've been looking at options in aftermarket like vintage air, but I cannot figure something that I think I can shoehorn inside a Puma dash, or can be easily adapted to mount in the engine bay on the bulkhead.

To that end I am considering fabricating a replacement hvac box. I'm not looking to manufacture these for sale, I'm hoping to come up with an open source design that other DIY fabricators could build.

The box design can be cut from sheetmetal with a few bends on a brake. Anyone who can get metal cut from a DXF ought to be able to get the sheet metal cut in a flat pattern. Bending into the correct shape could be done with a proper CNC press brake, manual brake, or by hand.

So the 3 off the shelf elements I am trying to source to make this happen are:

Centrifugal fan

Heater Core.

Ac Evaporator.

I've been looking at options from common vehicles that could be adapted to fit in a defender sized hvac box. This GM unit with expansion valve from a picture seems like it would work, but the dimensions are unknown, and the expansion block valve doesnt have standard #6, #8 type threaded fittings, so finding a mating fitting to makeup a hose might be an issue.

Amazon.com: ACDelco GM Genuine Parts 15-63852 Auxiliary Air Conditioning Evaporator Core, Black : Automotive

Buy ACDelco GM Genuine Parts 15-63852 Auxiliary Air Conditioning Evaporator Core, Black: Core Assemblies - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

I know from experence that the 1996- Jeep XJ has an evaporator that connects directly to a TXV with more standard threaded fittings:

And the 1997+ XJ changed fittings and uses an orifice tube instead:

So there is a plethora of off the shelf options, but hard to find information on dimensions online, and many newer vehicles use push lock and other less standard fittings that are a little more trouble for us in the aftermarket world. I'm also not keen on trying to do an orifice tube in an aftermarket application, my gut says sticking with TXV will work better than trying to size an orifice.